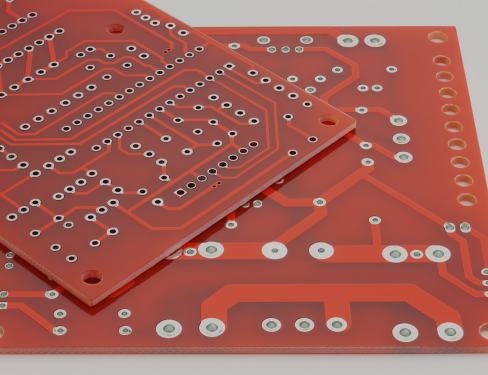

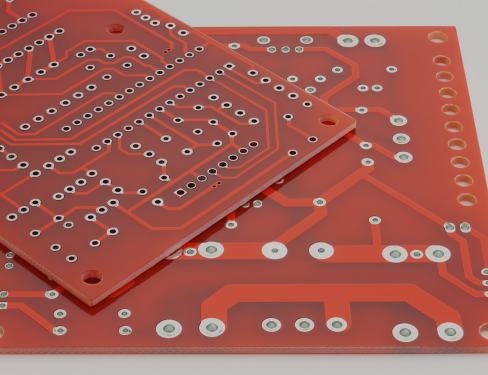

Single sided PCB’s are best suited for low-density designs and are easily designed and manufactured, and we have specific suppliers who specialize in these types of boards and therefore offer unbeatable prices for both small and large production runs.

Our single sided boards are available with standard and non-standard substrates, and a choice of surface finishes.

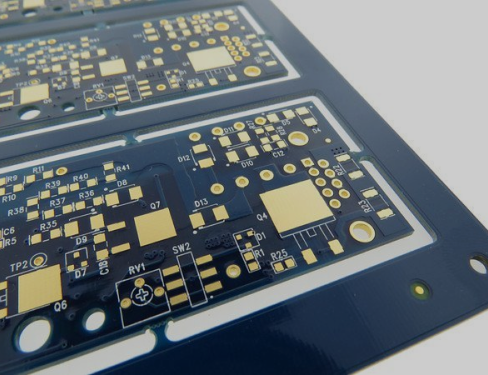

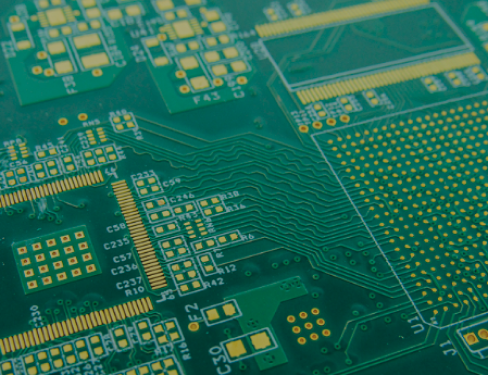

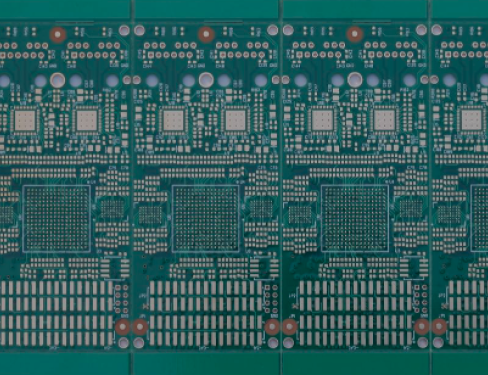

Today the double sided printed circuit board technology is the most widely used in the electronics industry. There are endless applications for old and new designs and many choices for substrates, solder resists, legends, and surface finishes.

We here at JD Photodata know exactly who to manufacture your board with some better equipped for low volume runs and others who offer exceptional value on higher volume runs.

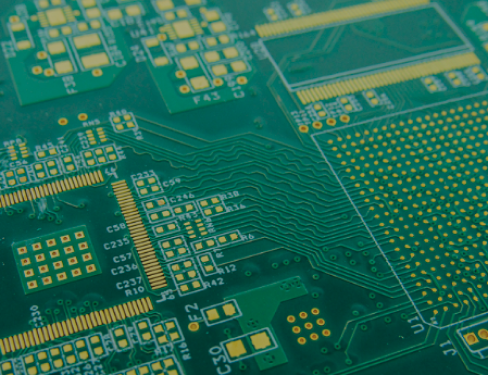

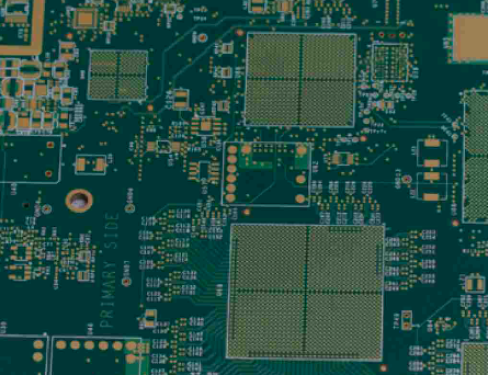

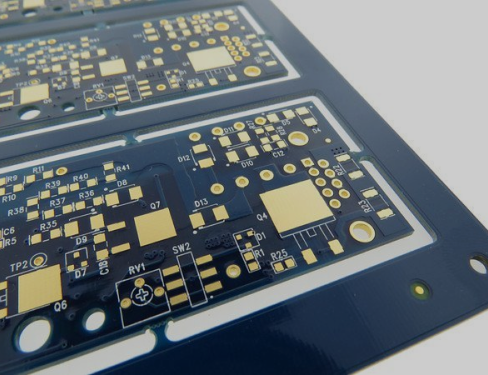

Suitable for all designs with high packing density, multilayer boards are indispensable for modern HDI layouts.

Whether you require 4 layer up to 100-layer boards, our highly trained in-house engineers working closely with our annually audited suppliers are able to produce all your most complex designs.

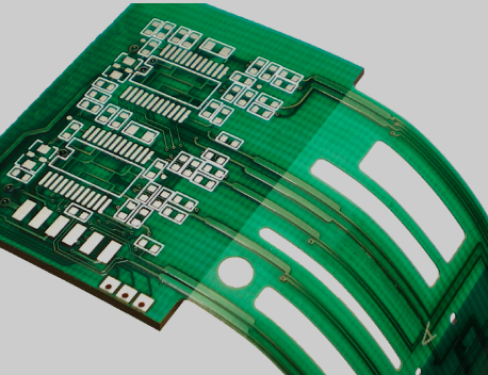

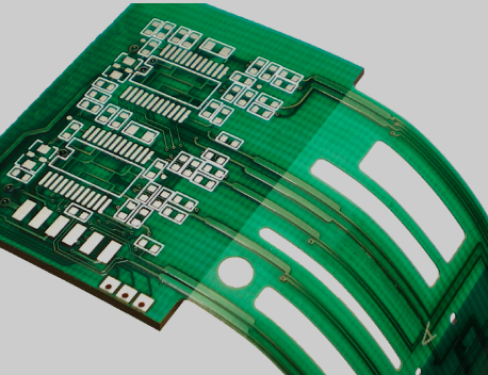

Flexible circuit boards are becoming ever more popular. They can be manufactured using the identical components as a rigid board allowing the board to conform to a required shape or actually flex during its use.

Typical materials are Polyimide, PEEK, and Polyester Film. From single sided up to 10 layers we can supply Flexible circuit boards of the very best quality backed with our low-cost principles.

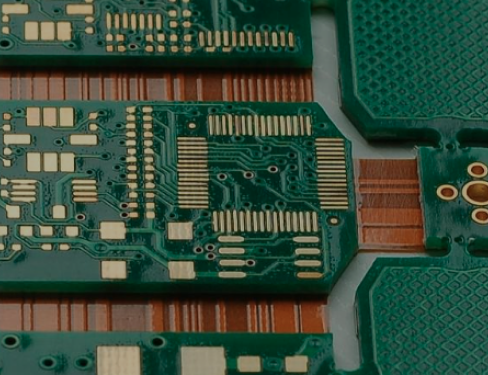

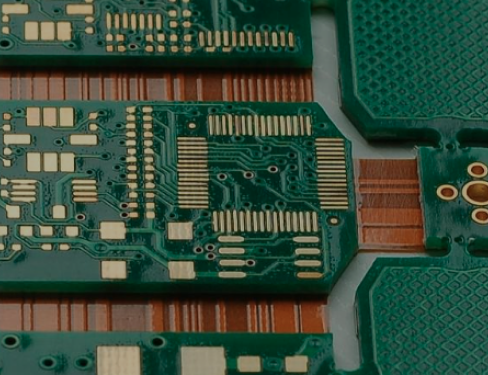

Flexi rigid PCB’s are composed of a combination of flexible and rigid substrates laminated into a single structure.

Plated Through Holes (PTH) are used to electrically connect the two sections. The application of Flexi/Rigid PCB’s offers optimum solutions for difficult limited space conditions. Used extensively in the Aeronautical Industry where space and weight are at a premium, this type of PCB can also save money.

The rise in LED technology from conventional bulbs and lamps has necessitated the need for PCB’s to be able to counter the heat generated by LED’s.

Standard FR4 boards on their own tend to burn and subsequently fail in high temperatures. Therefore, to alleviate this issue metal backed PCB’s are used which in essence are thin PCB’s bonded with either Aluminium or Copper of varying thicknesses. The result of this backing means that any excess heat passes through the FR4 substrate and is drawn in by the Aluminium or Copper thus stopping the actual PCB from over-heating.

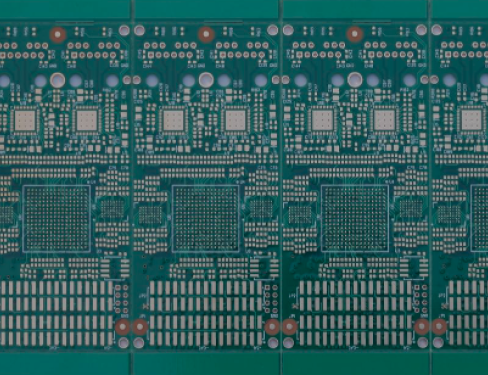

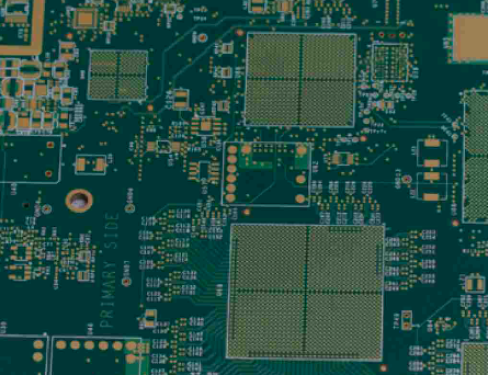

HDI boards are becoming ever more popular and require special processes and equipment to match the high spec technology of these boards.

HDI boards contain blind and/or buried vias and often contain micro vias of .006 or less in diameter. There are 6 main types of HDI boards, through vias, blind & buried vias, two or more HDI layer with through vias, passive substrate, coreless construction and alternate constructions.

The increasing complexity of electronic components and switches continually requires faster signal flow rates and thus higher transmission frequencies.

Because we at JD Photodata regularly audit our UK and Far East suppliers, we know exactly the right people to produce the right product for you. Whether you require Rogers, Taconic, Teflon or something more unusual, let us take the stress out of finding the very best manufacturer for your requirements.